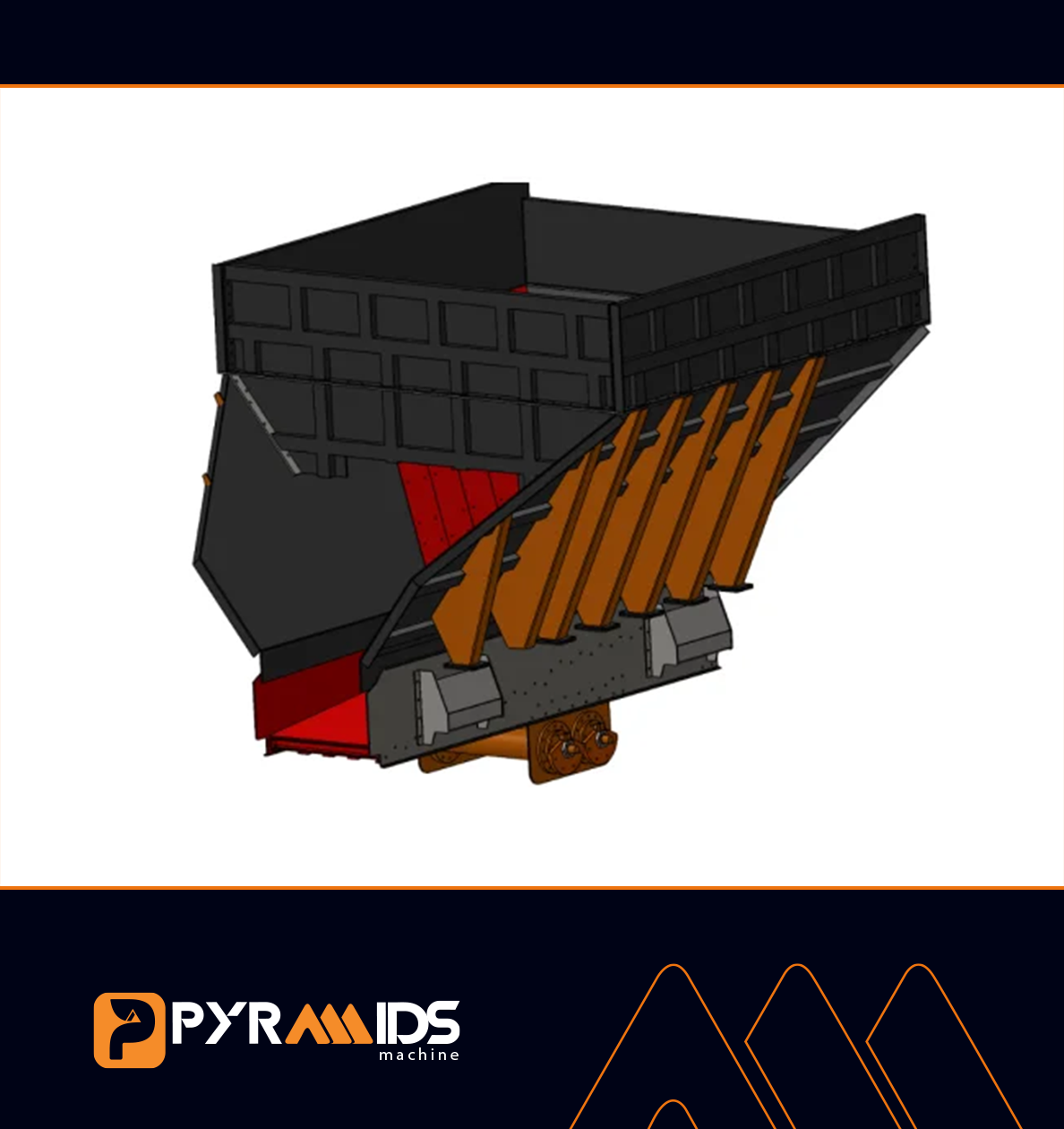

APRON FEEDERS

Pyramids Apron Feeders are designed to operate both horizontally and at an incline. They consist of overlapping, abrasion-resistant pallets fastened to chains with bolts, functioning similarly to a conveyor. These chains, connected to the pallets, are powered by chain gears located on both sides, ensuring reliable material transport in various operational conditions.

![]() squareagency

squareagency